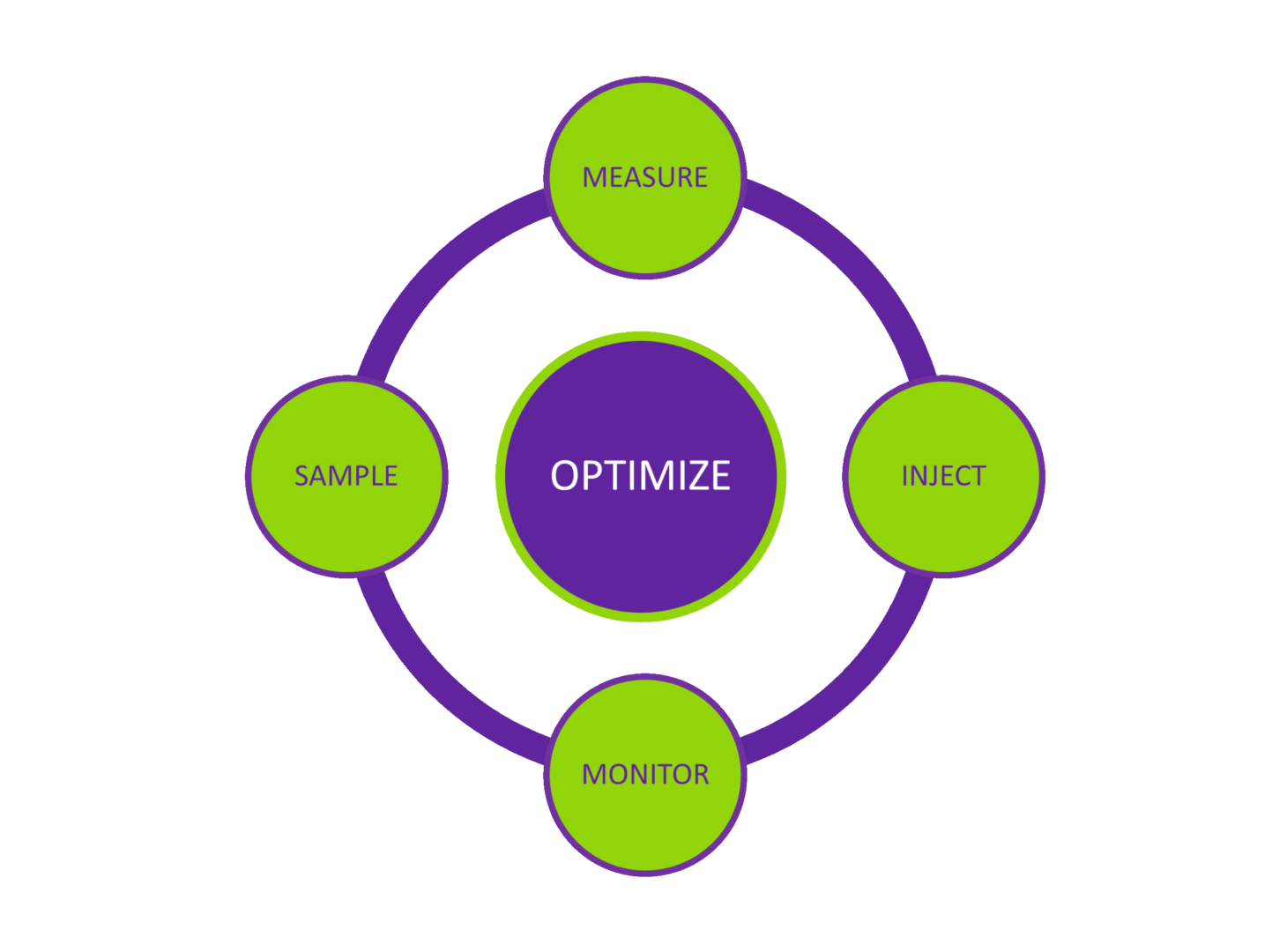

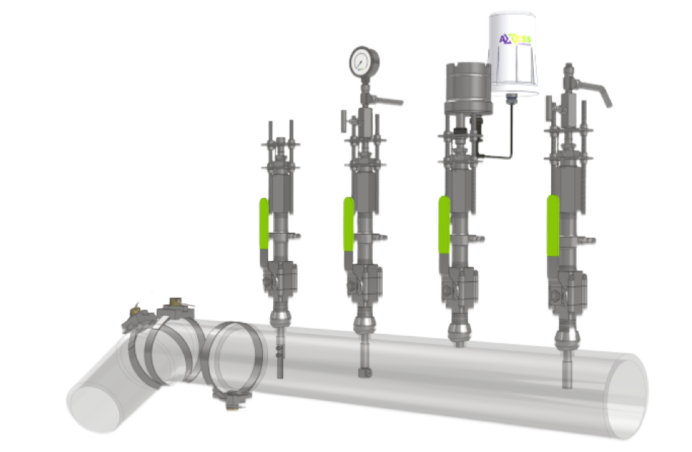

The injection of chemical treatments and sampling of process fluids are two major requirements for any corrosion control system. Often corrosion monitoring systems are selected to evaluate and optimize chemical injection performance. Axess provide systems that can be serviced online using the same retrieval tools used for corrosion monitoring devices, or fixed flanged systems. A range of quills and atomizing nozzles can be provided in many different materials. Wake frequency and atomization calculations are provided free of charge on every project managed by Axess.

Chemical Injection and Sampling

Whilst many injection and sampling systems can only be serviced and maintained during shutdown conditions Axess provides a range of high and low-pressure injection and sampling systems which can be serviced safely online at pressures up to 6,000 PSI / 413 Bar and temperatures up to 232°C / 450°F. Retrieval tools and some spare parts are common with the corrosion monitoring equipment using the same access system. Costs can therefore be reduced.

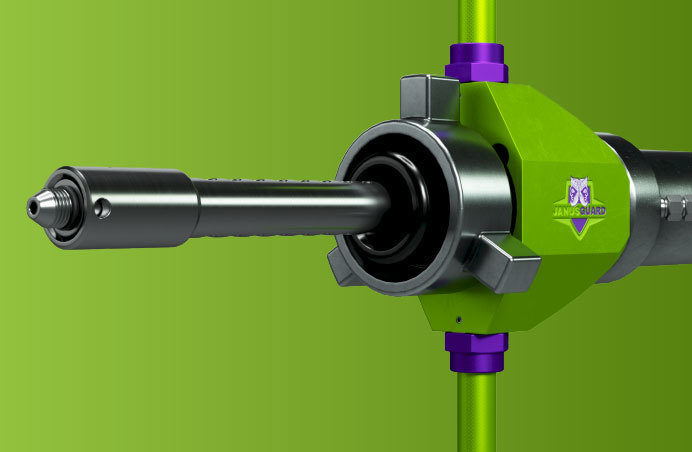

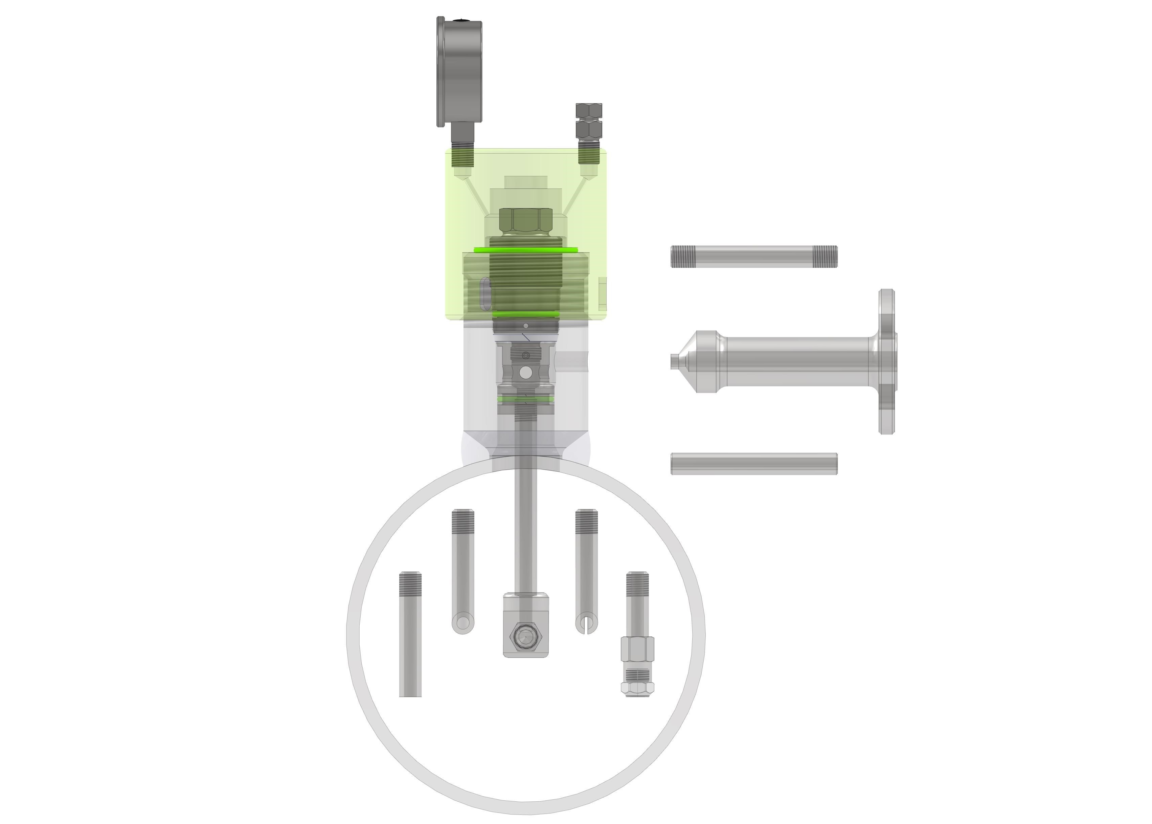

Direct Injection

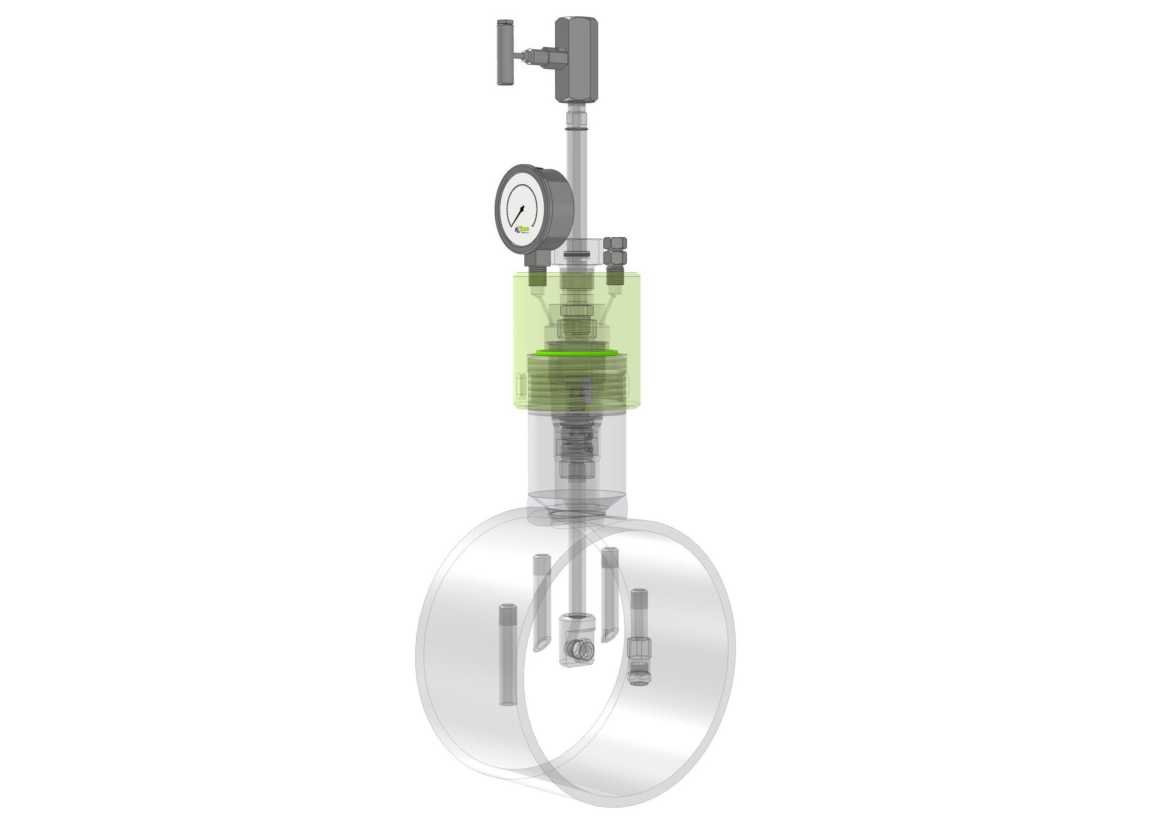

The Axess Direct Injection system provides an alternate solution allowing the use of non-tee fittings whilst still maintaining the safety, reliability, and online servicing capability of our side tee systems including secondary isolation with pressure retaining cover. These fittings provide the flexibility to repurpose existing monitoring fittings or allow installation of new injection points at critical locations where space may be restricted.

The Direct Injection system incorporates two internal one way check valves built into a Hollow Plug. This allows chemical to be injected into the line through the center of the plug, and prevents flowback of process into the injection line.

Selecting Your Injection and Sampling Hardware

The rate of chemical injection (gallons/day) is determined by the min/max capacity of the injection pump. Using an atomiser, in a gas system where appropriate, can certainly help with fine volume control by adjusting the injection differential pressure and maintaining a constant application of the chemical. Chemicals that are injected using an open quill are applied in a pulse method with the frequency determined by the stroke rate of the chemical injection pump. In most cases the preferred method is to have a low stroke volume with a high stroke frequency to minimise the time between each pulse injection of chemical.

Chemical injection points should always be located upstream of the equipment and pipework requiring protection. In piping systems where there is a change of material (e.g. duplex at the well heads and carbon steel further down line), the injection point should ideally be located a minimum of 10 x pipe ID upstream of the change in material. The ideal injection location is normally centre line however for higher velocity processes, wake frequency / drag calculations should be considered to determine maximum length whilst maintaining the integrity of the injection device. Axess provide these calculations with every quote and you can generate these yourself by utilizing our Project Kickstarter software.

Quill or Nozzle?

The injection head type should be selected based on the process, with quills normally being selected for fluids, and spray nozzles for gas. Nozzle sizes are selected based on the process line pressure, injection line pressure and desired injection rates.

Quills for Liquid Process or Multiphase Streams

For chemical applications in liquid process or multiphase streams the use of open quills are most commonly used. Open quills can also be used for the application of corrosion inhibitors in wet gas flowlines or gathering systems provided that the flow regime is sufficient to carry and apply the inhibitor around the full circumference of the line.

Atomizer Nozzles in Gas Treatment Applications

Atomizers are commonly used for the injection of H2S scavenger chemicals in gas treatment applications. In this type of application the use of an atomizer greatly increases the scavenging efficiency due to the fine dispersion of liquid scavenger chemical throughout the gas phase. If H2S scavengers are applied using an open quill in dry gas applications the treatment efficiency can be reduced as the liquid scavenger chemical can quickly fall to the bottom of the line resulting in less contact of the H2S molecules throughout the gas stream. As a result, the volume of chemical required to achieve the same level of scavenging performance is generally much higher, as you need to overdose, with associated increase in treatment cost required to achieve on-spec gas, commonly < 4 ppm H2S for sales/export gas pipelines.

Injecting Corrosion Inhibitor

Many systems and processes can suffer from performance issues related to corrosion in various components such as piping, heat exchangers, pumps, valves, etc. Corrosion can affect the safety and mechanical integrity of a system by degrading materials and components.

For applications of corrosion inhibitor in wet gas streams where the gas velocity is low e.g. a laminar flow regime, the use of an atomizer can improve the efficiency of treatment by maintaining a higher level of dispersion of fine inhibitor droplets throughout the gas phase as it traverses the line allowing contact of the inhibitor to provide a protective film around the full circumference of the line. Spray nozzles coupled with Axess injection fittings and hardware can distribute the inhibitors as evenly as possible along the center line of process streams or vessels.

Injecting H2S Scavenger

Scavengers are liquid chemicals that neutralizes and removes small amounts of problematic compounds, typically hydrogen sulfide (H2S), from bulk fluid streams. H2S is a very hazardous and corrosive gas encountered in the oil and gas industry during the extraction, storage and transportation phases of hydrocarbon processing. H2S removal is critically important to prevent damage to expensive infrastructure and to ensure compliance with environmental and safety regulations.

Compared to open-ended injection quills, spray nozzles are designed to maximize efficiency in scavenger injection applications as they atomize and distribute the neutralizing liquid into the process stream which increases the reaction surface area that combines and reacts with H2S or other problematic compounds in the pipeline. Axess injection fittings and hardware can distribute the scavengers as evenly as possible along the center line of the process stream to help avoid wall contact or pooling.

Important Factors to Consider

- Chemical density and viscosity

- Process pipe/vessel size, velocity, pressure, temperature, and fluid composition

- Available installation ports and required clearance diameters

- In general process piping applications, a minimum of 3-5 pipe diameters of straight length upstream and 5-10 pipe diameters of straight length downstream are recommended to ensure spray dispersion

- Required materials of construction for corrosive environments

- Ease of maintenance/replacement

- Retractable lances allow for quill/lance removal while leaving the process online

- Required chemical flow rate

- Pressure differential

- Availability of steam, compressed air, nitrogen, or other carrier/atomization gases.

- Axess will help you specify the correct nozzle and ensure the devices supplied pass wake frequency / drag force calculations.

“Great to work with this team on all of our corrosion monitoring for our customer. They provide very prompt feedback to all of our questions. They are well versed in the equipment they supply. Looking forward to the continued support from Axess.”